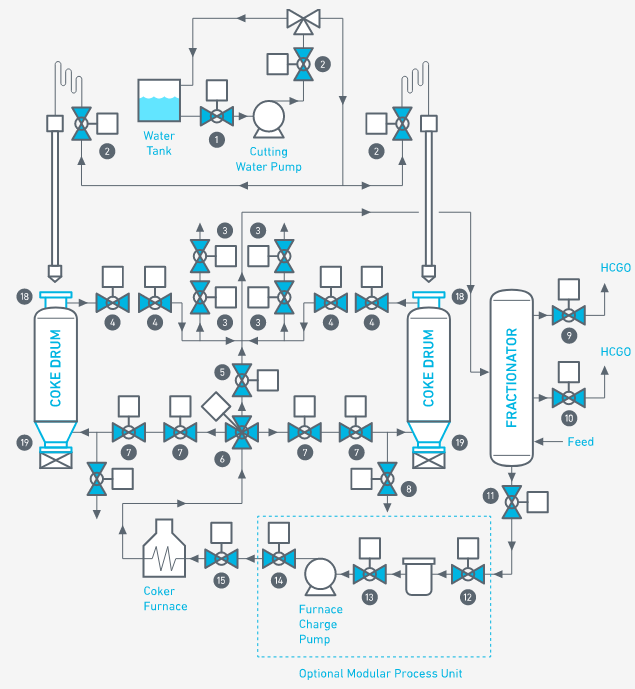

FLOW

DIAGRAM

Shut-off and control valves play an important role in delayed coking and for ensuring trouble-free distribution of the operating environment. The quality and reliability of valves have a great influence on the entire coking process. When choosing valves, it is necessary

to take into account all the existing features of a particular production and process. Valves used in severe operating conditions should not be mass-produced ones. Each product should be tailored according to the Customer’s requirements and the existing process.

1. HP Pump Inlet Isolation

2. Cutting Water Pump Isolation

3. Quench Extraction

4. Overhead Vapor Isolation

5. Coke Drum Bypass Isolation

6. Coke Drum Switching

7. Coke Drum Feed Isolation

8. Quench Extraction Isolation

9. Light Coker Gas Oil Pump EBV

10. Heavy Coker Gas Oil Pump EBV

11. Frac Bottoms EBV

12. Coke Filter Isolation

13. Furnace Charge Pump Inlet Isolation

14. Furnace Charge Pump Discharge Isolation

15. Furnace Feed Isolation

16. General Utility Valves (Stream, Water, Condensation) (not represented in diagram)

17. Drain Valves (not represented in diagram)

18. TUD. Top Unheading Device

19. TUD. Bottom Unheading Device

CONTROL

VALVES

Our company selects and supplies shut-off and control valves for all production lines of delayed coking processes and other associated production lines. Such lines include piping systems for all decoking processes, as well as the open/close valves of the coke drums.

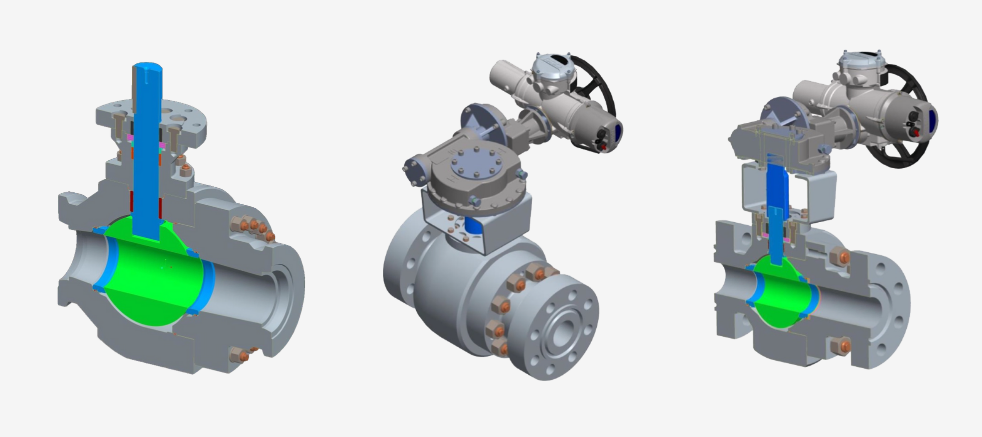

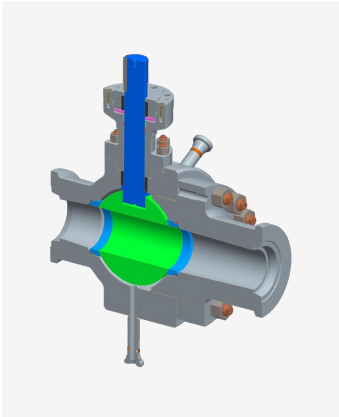

The flow shut-off and switching valves are one of the many factors that affect the quality and safety of the installation. These solutions are usually used in ball valves that are used in severe operating conditions.

Some basic valves are given below as examples.

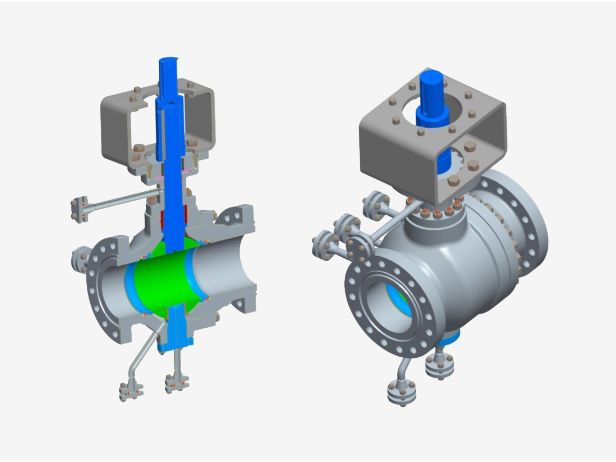

Specifications:

Size up to 16”;

Pressure up to 50 bar;

Temperature up to 520 °C;

Four-way switch 24-M ball valve:

Operational environment: heavy oil residues,

oil and gas, coke, steam.

Key features:

• Top access valve design, valve maintenance doesn’t

require pipeline dismantlement;

• One-piece design of ball and shaft;

• No delay when switching and the capability

to switch frequently;

• Special design of the valve seat system with

metal valve seal;

• Valve design with a pipeline inspection gauge and

exclusive hard-facing deposit of the ball and seats

Perrit 03.

• No deposits on the ball surface.

• High wear-resistance.

• Seat spring-loaded area, protected with graphite

rings and lock-free seat system;

• Steam purge on important valve assembly

and valve surfaces counteract the formation

of coke deposits;

• Hard-facing deposit Perrit 03;

• H2S Resistance;

• Triple position indication redundancy;

• Maximum reliability of the valve position indication

and, therefore, the entire process;

Specifications:

Size up to 24”;

Pressure up to 50 bar;

Temperature up to 520°C;

14-M shut-off valve:

Operational environment: heavy oil residues,

oil and gas, coke, steam.

Key features:

• The ball with suspension on the trunnion ensures

a high frequency of operation;

• Special design of the valve seat system with metal

valve seal;

• Valve design with a pipeline inspection gauge

and reinforced hard surface of the ball and seats.

No deposits on the ball surface;

• Seat spring-loaded area, protected with graphite

rings and lock-free seat system;

• Steam purge on important valve assembly

and valve surfaces counteracts the formation

of coke deposits;

• Hard-facing deposit Perrit 03;

• H2S Resistance;

• Triple position indication redundancy;

• Maximum reliability of the valve position indication

and, therefore, the entire process

Application range:

• Heating-up;

• Coolant drainage;

• Blowdown line;

• Bypass;

• Steam removal;

• Coke drum shut-off;

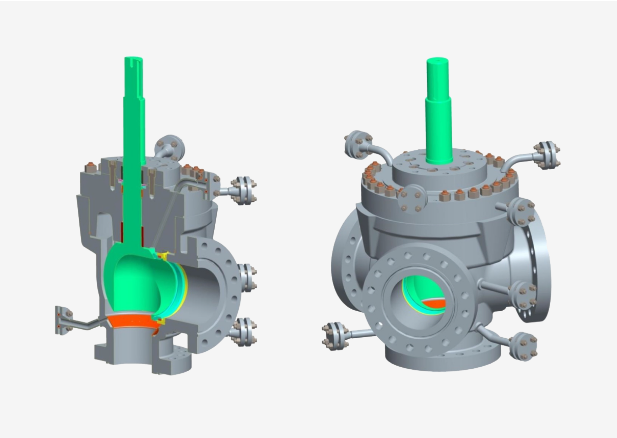

70-K shut-off valve:

Operational environment:

Gas with solid inclusions.

Application:

Internal shut-off valve;

Operational environment:

Gas with solid inclusions;

Design:

200 bar at 566°C;

Operation:

10 bar at 538°C;

Specifications:

Size up to 24”;

Pressure up to 50 bar;

Temperature up to 520°C;

80-M Shut-off valve:

Operational environment:

Water.